1. Electric motor¶

An electric motor is a machine that transforms electrical energy into mechanical energy of rotation. Electric motors are widely used to produce movements in toys, household appliances, transportation vehicles, power tools, industrial machines, water pumps, etc.

The electric motor can also behave like an electrical power generator when forced to turn. This electricity generator is much cheaper and more durable than electrochemical batteries.

The electric motor. PDF format

The electric motor. Editable format DOC

History of the electric motor¶

In the 1820s H. C. Ørsted and Michael Faraday discovered the basic principles of electromagnetism, necessary to build motors.

Between 1834 and 1838 the first practical electric motor was developed, which served to drive a boat for twelve people in Saint Petersburg.

In 1866 Werner von Siemens patented the dynamo, starting the production of electricity industrially, with direct current.

Starting in 1880, direct current networks and power plants began to be built in many countries, including Spain.

In 1888 Nikola Tesla made the first alternating current motor. This form of current is the one that ended up being used in electrical distribution networks thanks to its advantages over direct current and thanks to the patents freely assigned by Tesla to Westinhouse.

History of the electrification of Spain¶

In Spain, the first company that produced and marketed electricity (Sociedad Española de Electricidad) was created in 1881 in Barcelona. However, it was not until many years later when electricity reached all homes in a massive way.

| Year | Generated energy | Households with electricity |

|---|---|---|

| 1940 | 2 TWh | 30% |

| 1950 | 5 TWh | 45% |

| 1960 | 12 TWh | 65% |

| 1970 | 20 TWh | 85% |

| 1980 | 50 TWh | 95% |

| 1990 | 90 TWh | 100% |

Engine classification¶

- Brushed motors

- DC motors

- Universal AC motors

- AC induction motors with wound rotor

- Brushless motors

- Synchronous induction motors

- Permanent magnet brushless motors

- Reluctance motors (stepper motors)

Linear motors

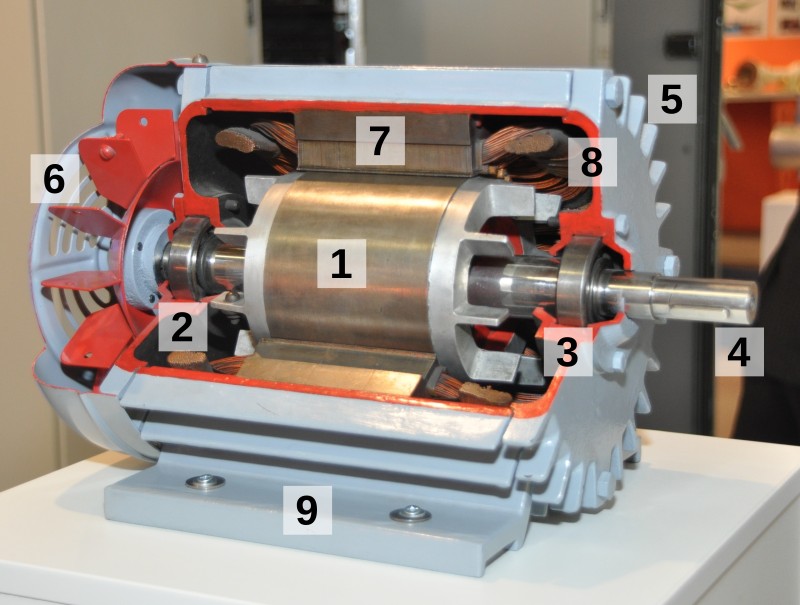

Motor parts¶

An electric motor is made up of two large blocks. The stator, which remains stationary, and the rotor, which rotates when the motor is running.

Parts of an alternating current induction motor, open to see inside.¶

- Squirrel cage rotor (induced).

- and 3. Bearings that hold the rotor shaft.

- Rotating shaft that carries mechanical energy.

- Housing with cooling fins.

- Fan with blades that cools the casing.

- Stator generating a rotating magnetic field.

- Stator coils powered with alternating current.

- Stator support foot to fix to the motor.

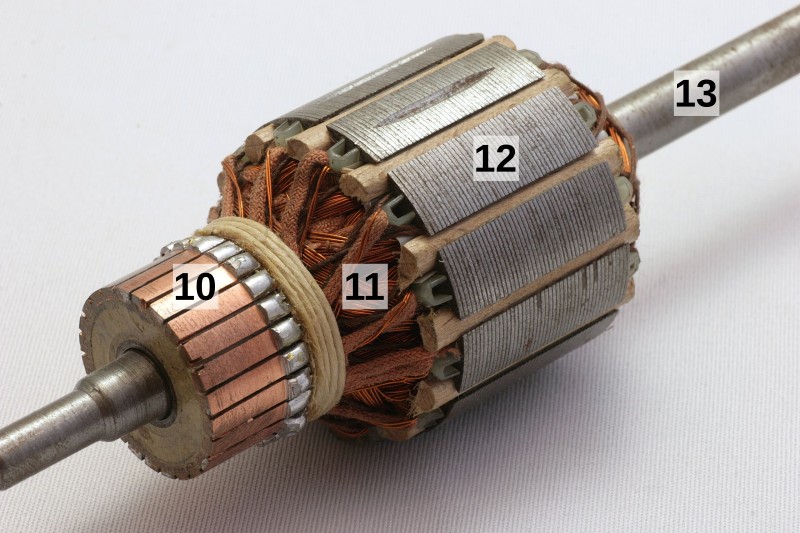

Rotor of a DC motor.¶

- Manifold with connection rods.

- Winding of copper wire (rotor coils).

- Rotor magnetic poles.

- Rotor axis of rotation.

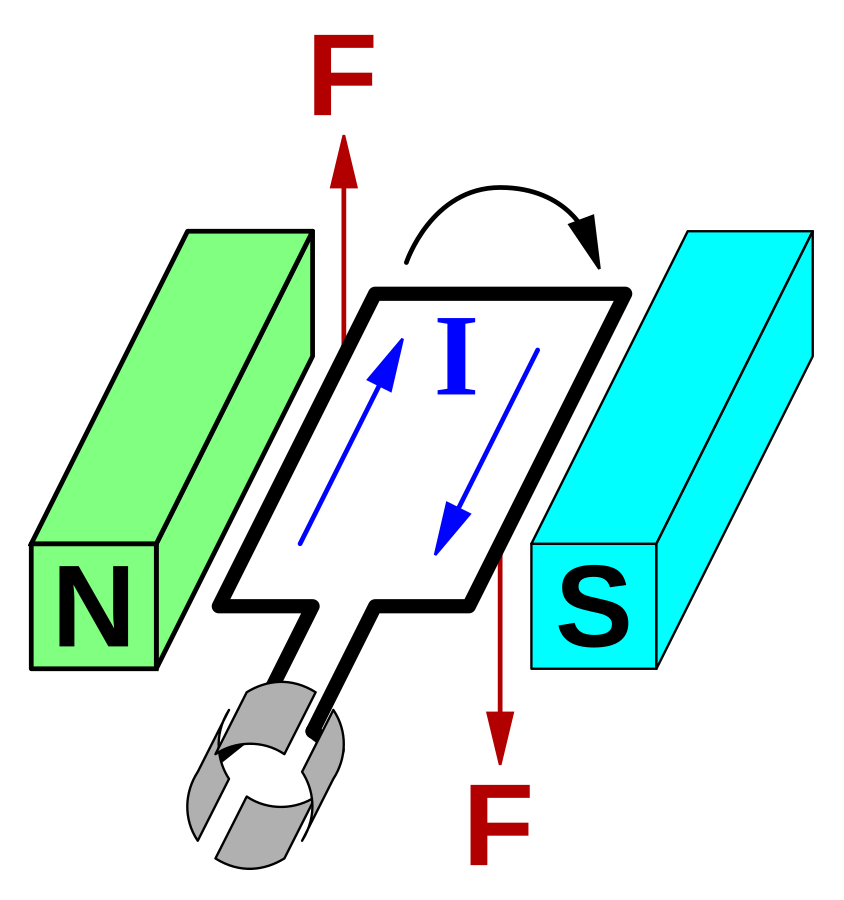

Electric motor operation¶

The operation of the electric motor is based on the force exerted by a magnetic field on an electric current (Lorentz force).

DC motors have windings with many insulated copper wires (11) through which current passes from the commutator (10). The stator magnetic field is fixed, produced by permanent magnets or by an electromagnet. The magnetic field generates a force in the current that circulates through the copper wires that tends to rotate the rotor. If we reverse the direction of the current, the force also changes direction and the motor will rotate in the opposite direction.

As the rotor rotates, the commutator also rotates and feeds new rotor wires. In this way, the horizontal cables that produce turning force are always powered.

Explanation of the direct current or direct current (DC) motor.

In induction motors the rotor cables are replaced by conducting bars. The stator's magnetic field is rotating and drags the rotor bars with it in its rotation.

Manufacture of an electric motor¶

Experiment to build a small direct current electric motor.

Frequency inverter¶

A variable frequency drive is an electronic device that controls the motor's supply voltage and current.

The motor supply current is proportional to the turning force (motor torque). The supply voltage, and its frequency, is proportional to the speed of rotation of the motor. By controlling the current and voltage, the operation of the motor is precisely controlled.

One application of the variable frequency drive is to smoothly move the motors of the vehicles so that they have a constant acceleration. They can also control the speed of the means of transport. When the drive is running it produces an audible hum that is characteristic of train engines and electric automobiles.

Exercises¶

- What is an electric motor and what is it for?

- What is an electric generator and how does it relate to motors?

- Draw a time line showing the main milestones in the history of the electric motor.

- Draw a graph of the history of electrification in Spain. A line should appear with the installed power with the values on the left vertical axis in 15 TWh sections and another line with the percentage of households with electricity with the values on the right vertical axis in 10% sections.

- In approximately what year did 60% of households in Spain have electricity installed?

- Name 5 different types of electric motors.

- Draw an induction motor and name its main parts.

- Draw the rotor of a DC motor and name its main parts.

- Explain the operation of a DC motor.

- What is a motor frequency inverter and what is it for? Write an application example.

- How can you control the speed of rotation of a motor? And your torque?